| Min. Order: | 1 Set/Sets |

|---|

Basic Info

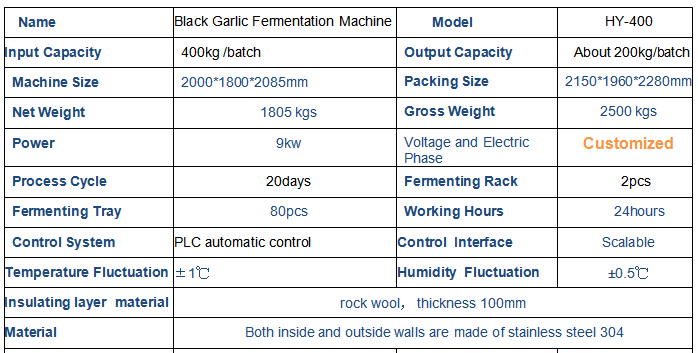

Model No.: HY-400

place of origin: China

status: New

Video factory inspection: Provided

Mechanical test report: Provided

Core component warranty period: 1 Year

Core components: Plc

warranty period: 1.5 Years

Out-of-warranty service: Video Technical Support, Online Support

Total Power: 6kw

Product: Black Garlic

Texture: Stainless Steel 304

Control System: PLC Intellgent

Name: Fermented Black Garlic Machine

Process Cycle: 18days

Output: 200kg Black Garlic/batch

Additional Info

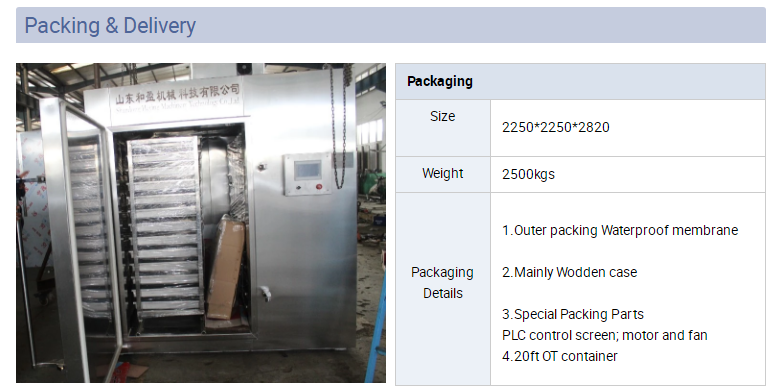

Packaging: 20ft container

Productivity: 30sets

Brand: HEYING

Transportation: Ocean

Place of Origin: Zhucheng,Shandong

Supply Ability: 30sets

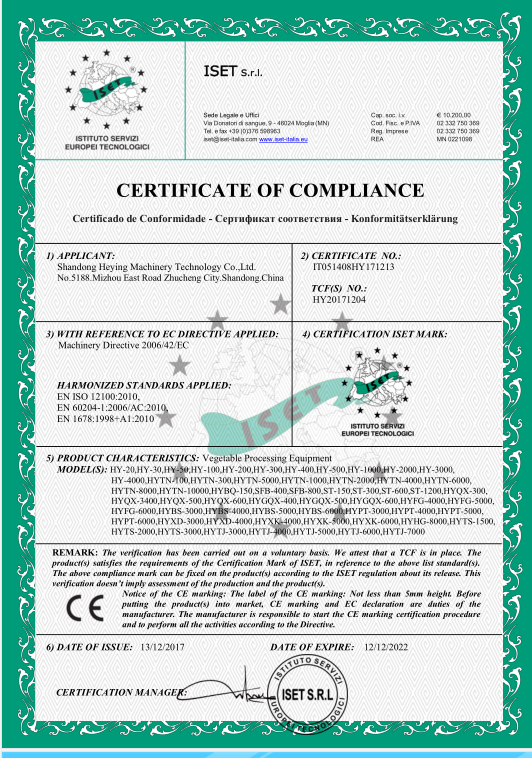

Certificate: CE

HS Code: 8419899090

Port: QINGDAO

Product Description

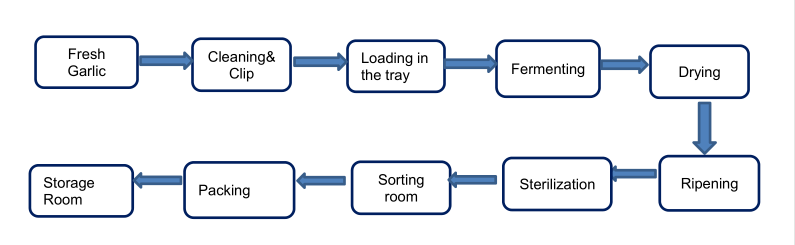

Black Garlic Fermentation Machine is also called Black Garlic Fermenter or Black Garlic Machine.It is mainly used in making Black Garlic.We use anhudrous fermenting technology to ferment. The process cycle is only about 18days for a batach.So, how to make black garlic?

Our machine can not only make peeled black garlic clove directly but also it can make whole bulb black garlic and solo black garlic.In you want to invest in some deep processing black garlic products, such as black garlic paste, black garlic juice , we can also provide some related machine for you.

Some Parameter of the HY-400 Black Garlic Machine

1.The perfect combination of technology and Whole Foods Black Garlic equipment, the whole process of fermentation without any added (including water)

2. Low power consumption .

3.The equipment has the advantages of simple operation, no wearing parts, no Maintenance, Low operating cost.

4. High degree of automation equipment, the whole process is controled by PLC intelligent system control to ensure product quality and stability.

5. Product taste sweet and mellow,Fermentation technology and other equipment just won't do the trick.

6. The material is 304 stainless steel material, no water, to avoid corrosion Equipment.

7. Fermented Whole Black Garlic Equipment Internal circulation is scientific .The heat preservation effect is good.Temperature is controlled within ± 3, fermentation product taste is highly consistent .

8.Due to advanced production technology, the follow-up of deep processing products tastes and quality are the international leading level

Packing and Certificate

FAQ